With news on: McCarthy Marland’s Doosan equipment; Devon Contract waste invests in MAC; Mobil-Inn installs Arbor’s smart systems; Lubo builds sorting installation for BPS Recycling; and, AD REM introduces ‘VULTURE’.

McCarthy Marland takes delivery of Doosan equipment

McCarthy Marland Limited, the waste and recycling company, has purchased two Doosan excavators and a Doosan wheel loader for the company’s Material Recycling Facility (MRF) in the St Philips area of Bristol.

The new Doosan equipment was purchased from local Authorised Doosan and Bobcat dealer, Kellands (Plant Sales) Ltd of Bridgwater in Somerset.

The DX140LCR-5 stage IV 15 tonne reduced tail swing crawler excavator offers increased performance, durability and fuel efficiency, with a focus on greater power, robustness and versatility.

The Doosan DL250-5 Stage IV compliant wheel loader has a bucket capacity of 2.5 m3, and is intended to meet a wide range of material-handling and loading applications.

Formed in 2001, McCarthy Marland was created service the market for the removal of both domestic and commercial waste and the company delivers and collects skips of different sizes every day throughout the South West.

Devon Contract Waste invests in MAC technology

Waste management firm, Devon Contract Waste, has invested in a MAC 111/1 baling press and MAC 1800P conveyor, supplied by RCP Systems, to bale paper, cardboard and produce RDF.

According to the company, the baler, which cost in excess of £500,000, is powered by twin 55 Kw motors with a baling ram force of 170 tonnes. Baling up to 50 tonnes of material per hour produces 1100mm x 1100mm x variable length bales, for efficient transportation.

The new “V” blade technology is noted to improve bale integrity and lower the cutting pressure when harder material is required to be cut as it is baled, making the chance of jamming less frequent.

Mobil-Inn installs trucks with Arbor’s Android terminal

Waste Collection company Mobil-Inn, based in Brittany, France, is equipping an increasing number of waste trucks with the company’s iSmartCollect solution.

The platform chosen by Mobil-Inn to complement this software is ARBOR’s 8″ IOT-800 rugged Android terminal.

According to Arbor, the iSmartCollect software provides simplified collection management, including seasonal variations, smart control, allowing circuit modifications, and reduces operating costs. iSmartCollect achieves this through real-time maps sharing, comprehensive human and material resource management, and enables real-time route modification.

The 8” IOT-800 terminal offers GPS navigation for geolocation and driver guidance, as well as a SIM card reader for communication with the collection centre. It also has an integrated NFC reader which allows employees with authorised badges access to the system/truck.

Arbor Technology (UK) Ltd a UK supplier of computing systems.

Lubo provides sorting installation for BPS Recycling

Emmen- Lubo Systems BV, part of the Bollegraaf Recycling Solutions Group, has received an order from BPS Recycling en Bouwstoffe in the Netherlands, to build a total sorting installation for processing construction and demolition waste.

The project is expected to be completed by the beginning of November 2017.

Lubo Systems BV supplier of complete recycling solutions and individual components. Lubo is, known for high quality solutions for construction & demolition waste, commercial waste and industrial waste.

The sorting machine will process C&D, skip waste, C&I, pre crushed concrete/aggregates and pre RDF. It will recover soil, concretes, inert (aggregates/ concrete/bricks), light fractions, wood, non ferrous, hard plastics, cardboard, foil, paper and pre RDF.

The installation includes a dosing feeder, long part separator, AWS 550, AWS 330, stretch deck screen, three wind sifters, overband magnet, and drum magnet. It has capacity to process 25 tonnes per hour.

AD REM introduces “VULTURE” for Zorba and IBA separation

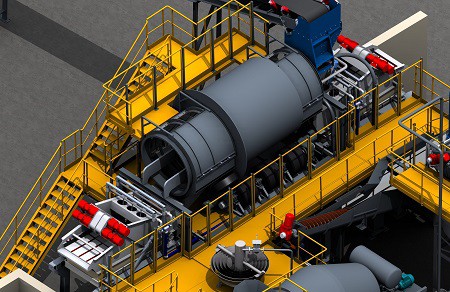

Recycling equipment company, Ad Rem, has developed the VULTURE, a compact and efficient installation for IBA separation.

The VULTURE separates ‘Zorba’ – a non-ferrous metal mix containing predominantly aluminum – or IBA by means of a flotation drum. The aluminum floats and is ejected out the front of the drum.

The sinks, consisting of heavy metals, are evacuated at the back. The medium fraction is drained from the material and the material is rinsed on vibratory screens. An internal water treatment system maintains a clean closed loop rinsing circuit. The system has a capacity from 10 to 40 tonnes per hour.

According to Ad Rem, its design team focused on reducing the medium consumption, saving 5 kg of FeSi for every tonne of Zorba material as opposed to other flotation systems. “This effectively enables recyclers to save more than $300.000 worth of FeSi annually for a 10 tonnes per hour system.”

The post Equipment news round-up (20/07/2017) appeared first on letsrecycle.com.

Source: letsrecycle.com Waste Managment