VIDEO REPORT: Funds raised from Packaging Recovery Notes (PRNs) and extended producer responsibility systems should be made available for innovators to develop new technologies to boost recycling.

The machine in Swindon is approximately one tenth of the size of the model which will be rolled out in Scotland next year

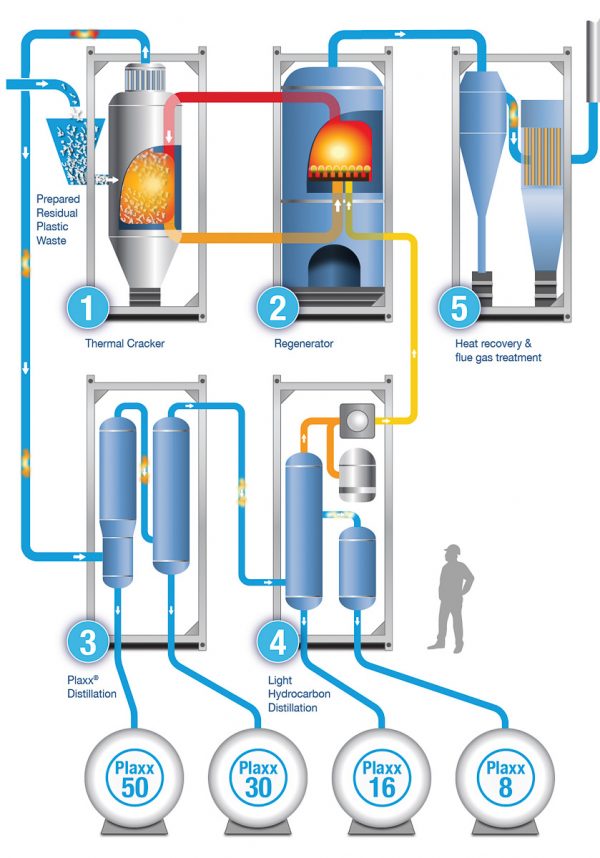

That’s according to Adrian Haworth, marketing and sales director at Recycling Technologies, the company behind a machine which it is claimed can turn waste plastic into a type of oil used in the petrochemical industry, with a reported value of more than £300-a-tonne.

Currently, the company has raised more than £10 million in funding to develop the technology, spread across seven rounds of crowdfunding as well as from ‘angel’ investors.

Zero Waste Scotland, a Scottish Government-funded body, has also awarded a grant worth approximately £3 million to fund the development of a site using the technology north of the border.

Recycling Technologies has agreed deals for the forward sale of ‘Plaxx’, the oil-product generated from its process. This includes deals with global commodity trader Interchem, and Kerax Limited, a wax manufacturer. The two deals are worth £50 million and £15 million respectively for the forward sale of its chemical and wax output.

Despite this, Mr Haworth says the waste industry needs a “better approach to funding innovative schemes”.

“We will again be crowdfunding soon, as we have had much success with that, and we will also be looking at venture capital funds. This will see us with enough working capital through 2019 and the build-up of the first machine” he explained.

Mr Haworth added: “However, I have to say we have yet to receive any funding from the industry, it has all been angel or high net worth investors. We feel the industry needs a better approach to this so that, for instance, funds being extended from extended producer responsibility or PRNS should be made available to innovators in the space to make this happen, to date it hasn’t.”

Pilot facility

The company currently has a pilot scheme in the council-owned Waterside Park facility in Swindon. In 2019, Recycling Technologies says it is on track to have its first full-scale machine in Perthshire, Scotland, which will be as part of a plastics recycling facility on a site owned by the Binn Group.

Some concerns have been raised over the potential viability of technologies seeking to turn waste plastics into oils due to the failure of similar plants developed in the UK in the past, particularly where public money is being used to support the development of the technology. But, Mr Haworth has claimed that these concerns should not deter investors from putting money into the project.

“Right now there hasn’t been any money from government,” he stated.

Mr Haworth added: “There has been a grant award which hasn’t been used. This is money from the government to support innovation where there are employment and environment benefits, there are many benefits as to why the government will want to see this.

“Of the £4 million in government grants we have received eight from private investors. This is only partially funded by the Scottish government. Nobody can claim the government is underwriting us, many private investors want a solution to waste plastic and also see an opportunity elsewhere to be in this space, so I can’t understand criticism when you consider we already have nearly 50 employees, many of which are high value jobs, taking in the best people.”

Click below to see Adrian Haworth explain more about the technology

Feedstock

Mr Haworth went on to say that in terms of feedstock, the facility can take a limited amount of contaminated material, and it’s hoped that in the long run, if the machine can give waste plastic a high value, it will stop contamination in areas which do not have sufficient infrastructure to collect and sort lower grade materials.

Mr Hawowrth concluded: “When we first started, we didn’t know where it [material] would be available from. After a short period we realised that when we said we could take waste plastic, we were inundated with requests to take it.

“Plastic is all over and we can take it out of the EfW streams quite easily, we expect all plastic on the market can be taken to a facility and be made into a new product. We do think, as has happened in Europe, all plastic can be collected separately. People should be able to say, if it looks like plastic and smells like plastic, collect it separately and we can take it to one of our facilities.”

The post Waste industry funding ‘needed to boost innovation’ appeared first on letsrecycle.com.

Source: letsrecycle.com Plastic