Packaging waste compliance scheme Ecosurety is working with three companies on a project to develop a chemical process to remove the pigment from black and other coloured rigid plastics.

The project has today (26 February) been awarded £800,000 in funding from Innovate UK – the government’s innovation grant scheme – to bring the technology to market.

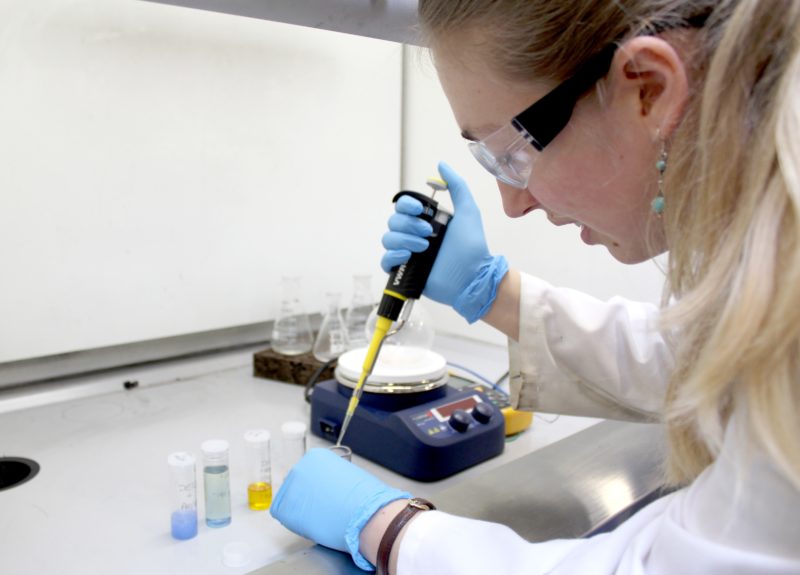

PolyMet is being developed by Impact Solutions and is a chemical process to remove the colour pigment from recovered plastics

Ecosurety is working with plastic technology firm Impact Solutions and Impact Recycling on the project, which has created ‘PolyMet’, a chemical process involving the removal of the coloured pigment from coloured and black rigid plastics, without destroying the polymer. The aim is to create a higher value, clear secondary polymer.

Ecosurety and Impact Solutions say that using PolyMet in line with current recycling processes, could create a “new stream of plastic feedstock at high volume and low cost”.

Funding

The Innovate UK grant will see Ecosurety provide consultancy support on the PolyMet project, offering market insights from its producer and reprocessor members to ensure the technology is developed in line with industry requirements.

A fourth company, McLaren Plastics will specify post-process material properties and validation of material suitability for injection moulding.

Tom Rose, innovation manager at Impact Solutions, said: “As plastic technology specialists, finding a solution to the 3.5 million tonnes of plastic material currently being dumped in landfill by the UK each year was a challenge we couldn’t resist.

“This £0.8 million Innovate grant is welcome recognition of the work we have undertaken so far and an endorsement of the positive impact that PolyMet could have for producers, reprocessors and on the environment.”

Chief executive of Ecosurety, James Piper, said: “The long-term objectives of Impact Solutions – to develop a technology that can add value to a plastic contaminant – fits perfectly with Ecosurety’s broader vision of driving forward positive change through increased recycling capacity in the UK recycling sector.”

Black plastic

Black plastics, used often in packaging such as food trays, are a problem for waste management firms when they are collected in mixed recycling loads, as they cannot be detected by Near-Infra-Read (NIR) sorting machines used in sorting facilities. Coupled with the problems sorting the material, there are limited outlets for it once it has been captured.

Black plastic trays are seen as a problem material as they cannot be detected in NIR sorting systems

Consequently, local authorities have been issued with advice to view the material as ‘non-recyclable’ and not to request it from households (see letsrecycle.com story).

While some retailers are now seeking to remove black plastic from their product ranges (see letsrecycle.com story) – other projects have sought to make the material easier to recover to allow it to continue to be used in new packaging and create a demand for the material at end of life.

A WRAP trial dating back to 2011 included work with retailers such as Marks & Spencer and Sainsbury’s to distribute black CPET with a ‘detectable’ additive that could be collected, sorted and recovered for use as food-grade plastic trays (see letsrecycle.com story).

Waste managment firm Viridor has worked on a pilot project to accept black plastic at its PRF in Rochester, Kent in the coloured rigids stream (see letsrecycle.com story).

Meanwhile, other companies have brought ‘detectable’ plastic packaging products to the market more recently. In 2018, the Welsh company Colour Tone launched a black plastic NIR detectable masterbatch for polypropylene applications.

And, this month, packaging manufacturer Quinn has launched its own detectable PET food tray ‘Detecta’ using a black colour additive that is identifiable using existing NIR equipment.

Commenting on the development, Thomas McCaffrey, new product development manager at Quinn Packaging, said: “In the last 12 months we have seen a growing desire within the food sector to move away from black coloured packaging. For Quinn Packaging this was short-sighted.”

The post Funding awarded for plastic pigment project appeared first on letsrecycle.com.

Source: letsrecycle.com Plastic